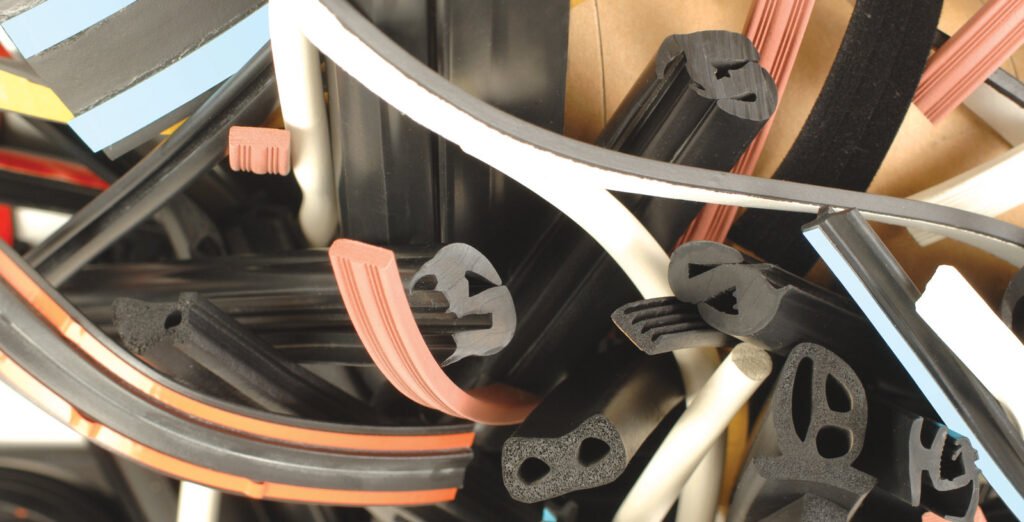

At Sonu Rubber Products, we specialize in the design, development, and manufacturing of precision rubber parts that power some of the most critical industries in India and across the globe. From automotive and engineering to construction, electrical, agriculture, and machinery – our products are engineered for durability, reliability, and performance.

With decades of industry experience, state-of-the-art infrastructure, and a commitment to quality, we have built a solid reputation as a leading rubber product manufacturer and supplier.

Innovation, Precision, and Performance

Innovation

We constantly push boundaries by adopting advanced technologies and fresh ideas to develop smarter, high-performance rubber solutions for modern industries.

Precision

Every product is crafted with exact engineering and strict quality control to ensure flawless fit, function, and durability in demanding environments.

Performance

Built to endure and excel, our rubber products deliver unmatched strength, flexibility, and long-lasting performance across various applications.

Why Choose Sonu Rubber Product

Quality Assurance

ISO-certified processes and stringent quality checks at every stage

Experienced Team

Skilled engineers and professionals with deep industry knowledge

Customization

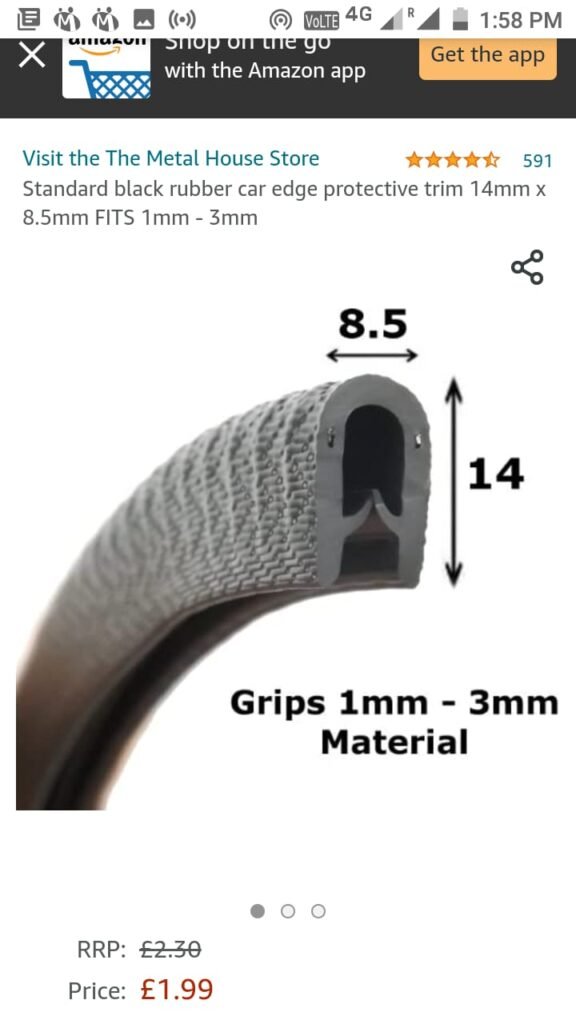

We develop tailor-made rubber solutions as per your design and requirements

Competitive Pricing

World-class products at cost-effective rates

On-Time Delivery

Efficient production and logistics to meet your deadlines

Eco-Friendly Practices:

We follow environmentally responsible production methods

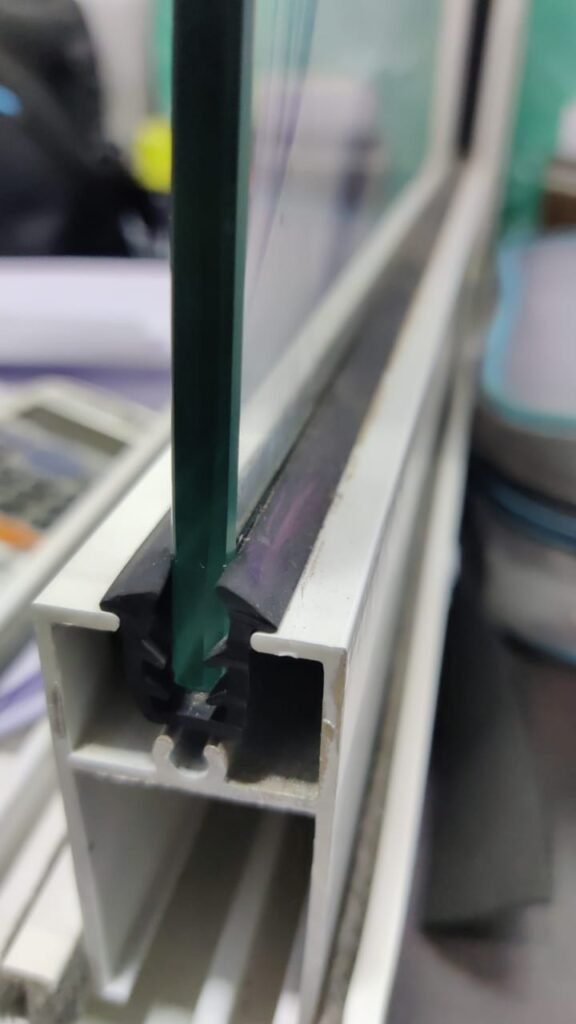

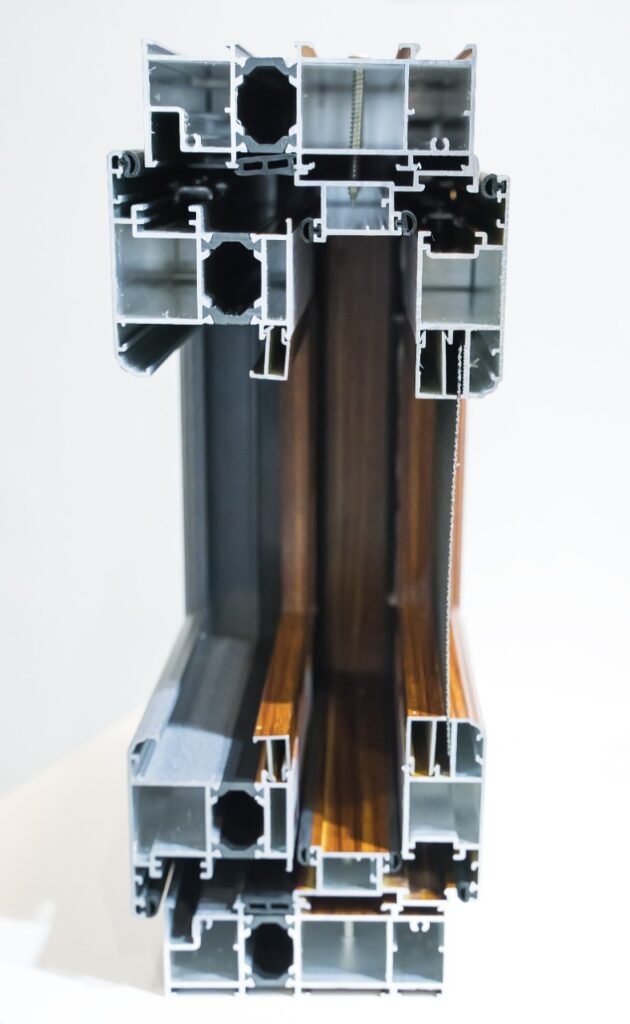

Sliding Window Rubber Cross Section

Railway window with rubber cross section cost

FAQ

Q1: What types of rubber materials do you offer for different applications?

We work with a wide variety of rubber compounds including EPDM, Neoprene, Nitrile (NBR), Silicone, Natural Rubber, SBR, and Viton. Each material is selected based on its thermal resistance, flexibility, chemical compatibility, and mechanical strength suitable for the intended application.

Q2: Can Sonu Rubber Products handle custom rubber part designs?

Yes, we specialize in custom rubber manufacturing. Just provide us with a technical drawing, CAD model, or physical sample, and our team will assist with design, prototyping, and full-scale production.

Q3: What industries do you serve with your rubber products?

We supply rubber components to a wide range of industries, including Automotive, HVAC, Construction, Electronics, Railways, Medical Devices, Food & Beverage, and Defense sectors.

Q4: What is your minimum order quantity (MOQ) for custom rubber products?

MOQ varies depending on product complexity, material type, and tooling requirements. However, we are flexible with small orders, especially for prototypes and trial runs.

Q5: Do you provide rubber-to-metal bonded components?

Yes. We manufacture a range of bonded parts including engine mounts, bushes, and vibration isolators using strong adhesives and advanced molding techniques for durable bonding.

Q6: How do you ensure the quality and consistency of your rubber products?

All products go through rigorous in-house testing including tensile strength, elongation, hardness, compression set, and chemical resistance. We follow ISO-certified quality protocols and provide testing reports upon request.

Q7: What is your average lead time for production and delivery?

Standard products are usually shipped within 7–10 working days. For customized parts, lead time may range from 15 to 25 working days, depending on tooling and design approval.

Q8: Are your rubber products compliant with international standards?

Absolutely. We manufacture components that comply with IS, ASTM, SAE, DIN, and BS standards. Our food-grade and pharmaceutical rubber parts are also FDA and REACH compliant.

Q9: Do you offer design assistance or engineering support?

Yes, we offer full support from product design to material selection. Our engineers and rubber technologists work closely with clients to optimize performance and cost-efficiency.

Q10: Can you export rubber products to international markets?

Yes, we regularly export to countries including the USA, UK, UAE, and Southeast Asia. We provide all necessary export documentation, packaging, and shipping support for global clients.

Mission / Vision

Mission

At Sonu Rubber Products, our mission is to deliver world-class rubber solutions that meet the evolving needs of industries worldwide. We are dedicated to providing precision-engineered, durable, and cost-effective rubber components that enhance the performance, safety, and reliability of our customers’ products and systems.

Vision

Our vision is to become a globally recognized leader in the rubber manufacturing industry by offering innovative, high-performance, and customized rubber solutions for every sector we serve.

Contact Us

Seamless Communication, Global Impact.

Reach out via our Head Office, Email, or connect with us on LinkedIn.

- BHAVIKA COMPLEX - Commercial Plot No. C-7+C-8 Survey No. 92/p in Umbergaon Notified Area village Dehri, Tal. Umbergaon, Dist: Valsad 396171

- sales@sonurubberproduct.com

- +91-8200805077